Manufacturing Quality & Testing

iConn implements structured quality assurance protocols and testing methodologies throughout the manufacturing lifecycle. Each phase, from incoming material inspection to final system validation, is executed to verify performance, ensure safety, and demonstrate compliance with defined customer specifications and applicable industry standards.

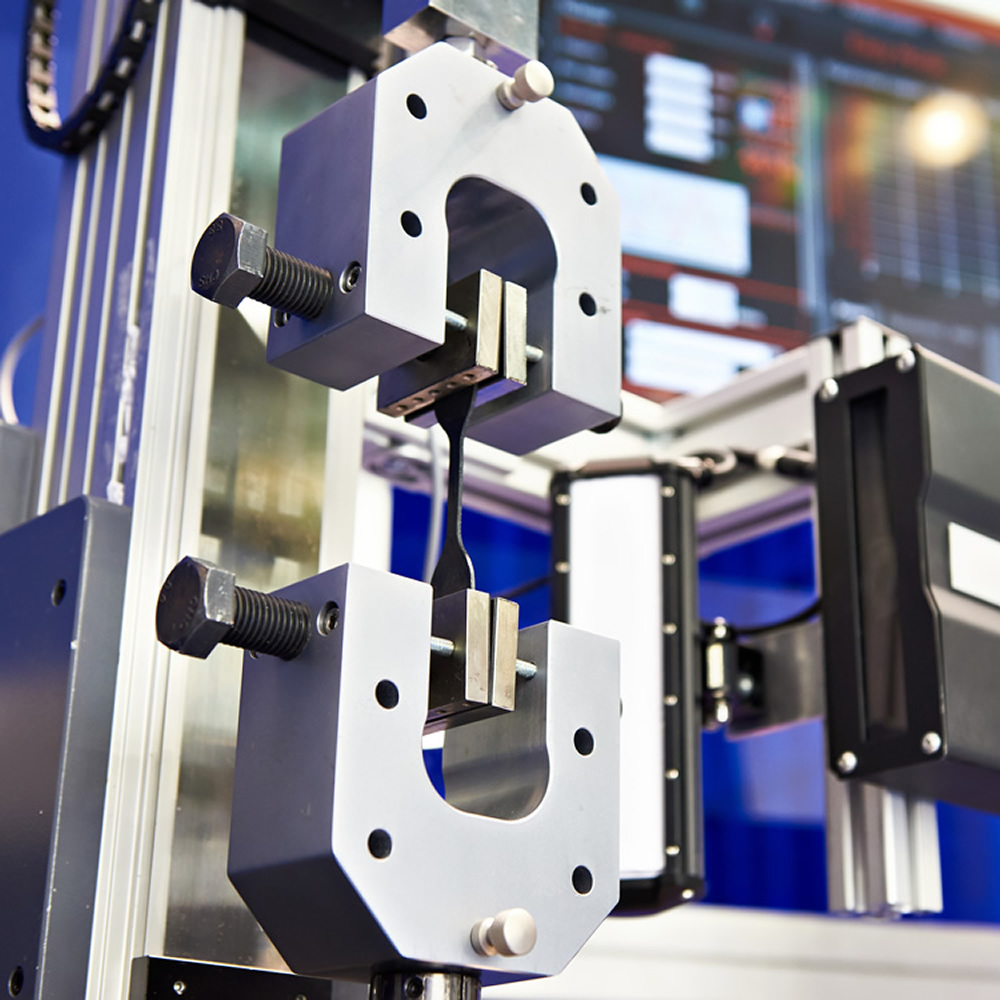

In-Process Quality Control

Quality inspections are performed in real time throughout the production workflow. Visual, mechanical, and electrical parameters are verified at defined checkpoints to ensure compliance with specifications.

Electrical Testing

Electrical validation includes continuity, insulation resistance, hipot, and functional testing. These procedures confirm signal integrity, insulation performance, and system-level electrical behavior.

Functional Verification

System assemblies are evaluated under simulated operating conditions. Functional checks are performed using customer-defined procedures to confirm expected behavior and integration performance.

Environmental Testing (Project-Dependent)

Environmental testing is conducted when required and may include temperature cycling, humidity exposure, shock, vibration, or other stress protocols to assess long-term durability.

Documentation and Traceability

Test results, inspection records, and part histories are digitally logged and retained. Complete traceability is maintained, and documentation is available to support customer audits or regulatory submissions.

Certifications & Standards

iConn's quality management system is structured to meet the requirements of ISO 9001 and other applicable customer or industry-specific standards. Calibration records, controlled process documentation, and internal audit logs are maintained to support traceability, regulatory compliance, and contractual obligations.