PCBA & EMS Assembly

iConn provides comprehensive electronic manufacturing services ranging from precision printed circuit board assembly (PCBA) to complete turnkey solutions. Each project combines accurate component placement with tightly controlled manufacturing processes to maintain consistent quality throughout production. Our capabilities accommodate early-stage prototypes, high-volume assemblies, and full system builds while meeting strict performance, reliability, and cost requirements.

Assembly Capabilities

Surface Mount Technology (SMT)

High-speed placement of surface-mount components using automated equipment, supporting tight layouts and complex assemblies.

Through-Hole Assembly

Manual and selective soldering for components requiring added durability, mechanical retention, or higher current handling.

Mixed-Technology Builds

Hybrid workflows for boards integrating both SMT and through-hole components, ensuring electrical consistency and build integrity.

Fine-Pitch and High-Density Assembly

Processes optimized for miniature packages and narrow pin spacing, ensuring precision and signal integrity.

EMS Services

Procurement & Supply Chain Management

Sourcing, inventory control, and vendor management to keep production efficient and cost-effective.

Box Build & System Integration

Final product assembly, wiring, enclosure installation, and functional testing for complete turnkey solutions.

Testing & Quality Assurance

In-circuit testing, functional testing, and inspection processes to verify performance and compliance.

Quality and Testing

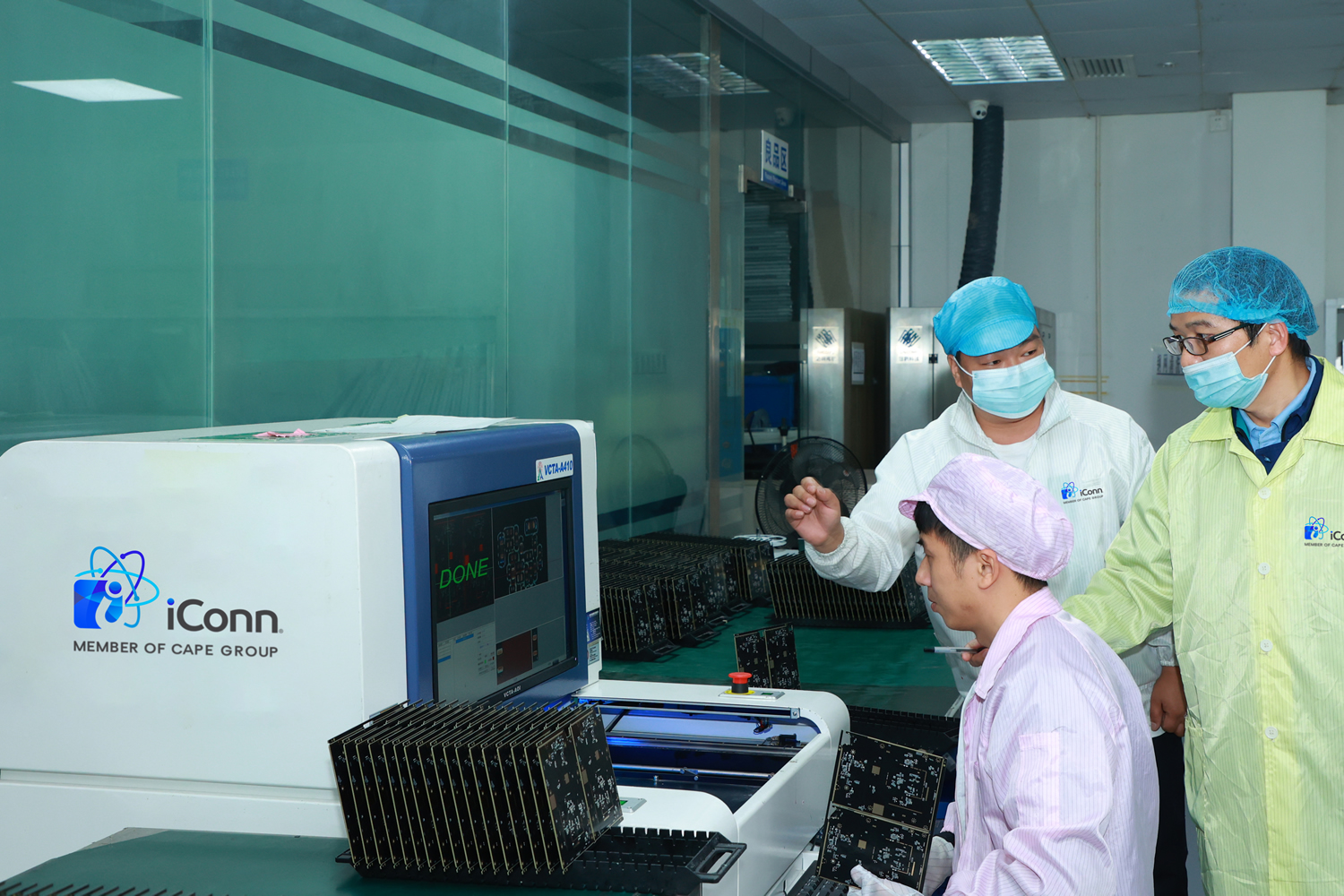

Automated Optical Inspection (AOI)

Automated optical inspection systems evaluate each PCB for correct component placement, polarity, and solder joint quality. High-resolution imaging and computer-vision algorithms identify defects early, reducing rework before functional or system-level testing.

Functional Testing

Functional testing includes in-circuit testing (ICT) at the board level as well as system-level verification for fully assembled products. These processes ensure that electrical performance, signal integrity, and mechanical functions meet all project specifications.

Production Scalability

PCBA and EMS services are structured to support low-volume prototyping, mid-volume pilot runs, and high-volume production. Processes are designed to scale efficiently while maintaining consistent quality, optimizing throughput, and meeting defined lead time requirements.