Plastic Fabrication

iConn provides precision plastic fabrication services for components and enclosures used in a wide range of applications. Each part is manufactured to meet defined mechanical, environmental, and dimensional requirements, ensuring durability and consistency. Our processes support both prototype and production volumes, delivering components that integrate seamlessly with electrical assemblies, mechanical systems, and finished products.

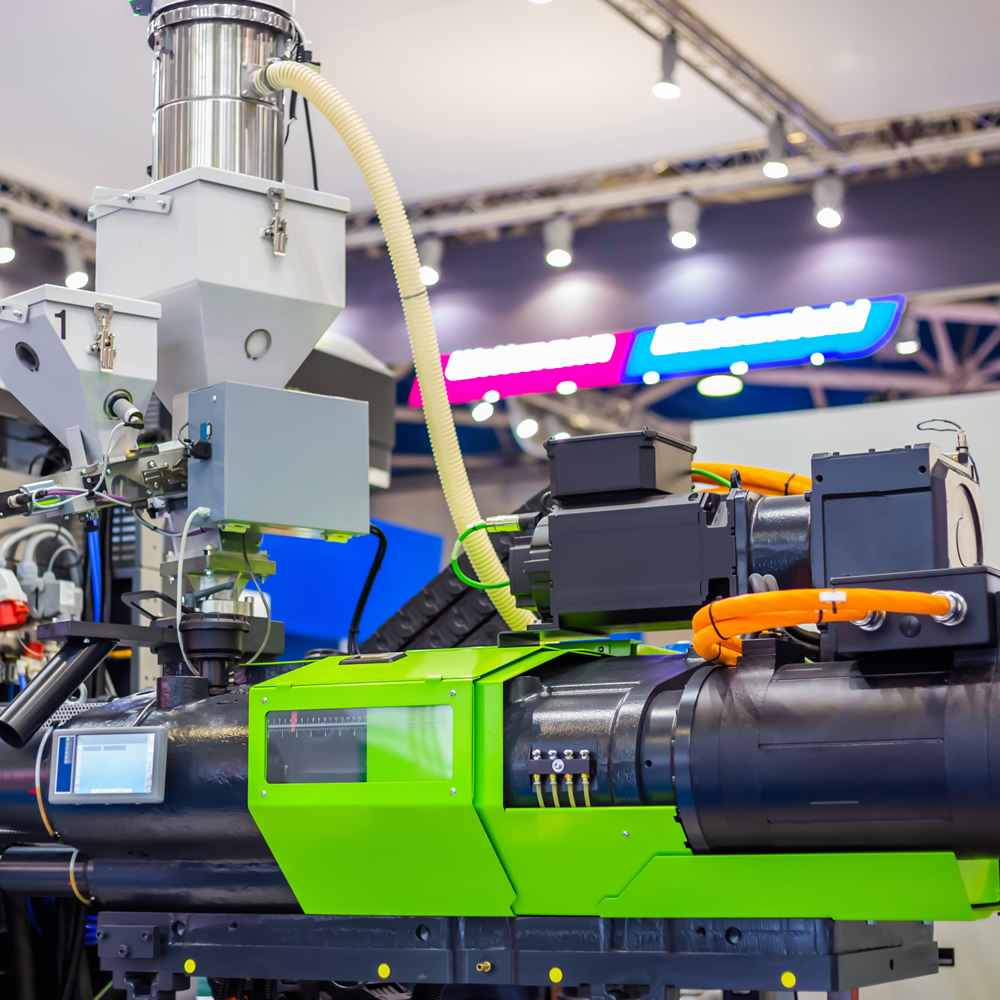

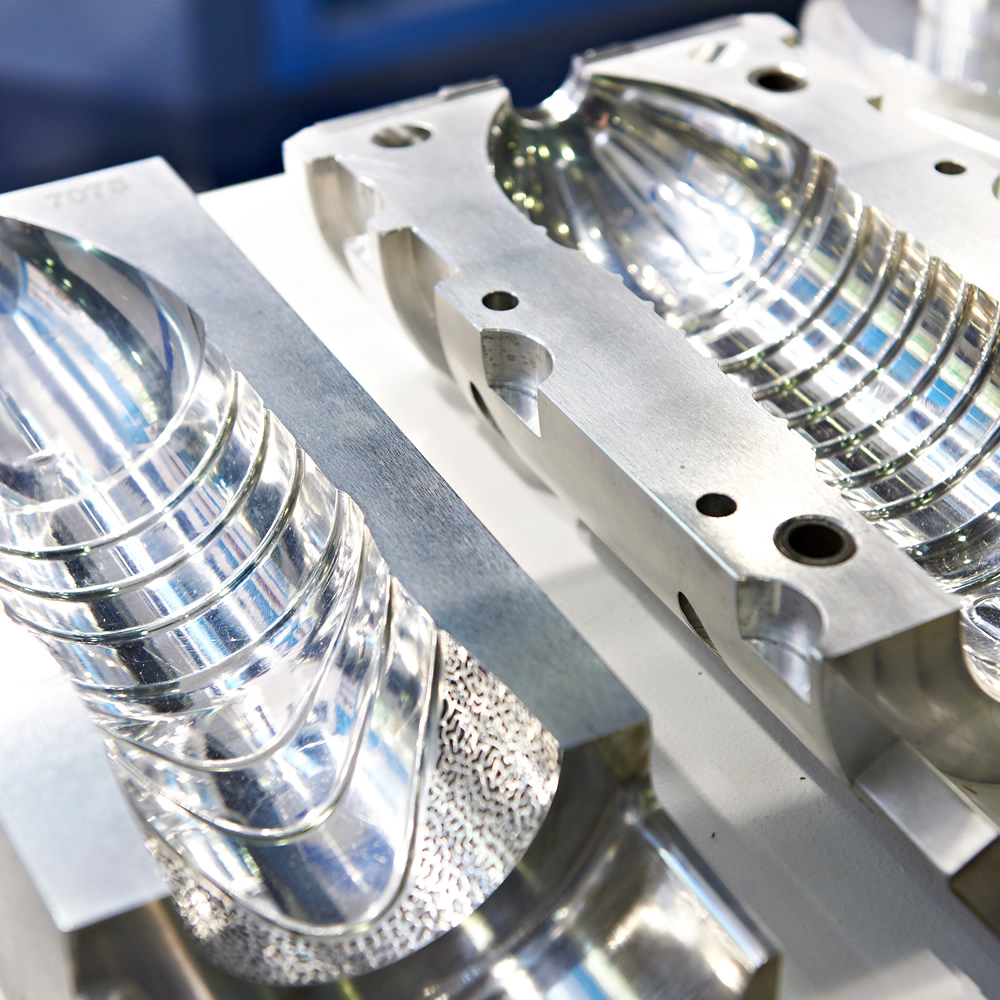

Injection Molding

Consistent, high-volume production of complex plastic components with precise dimensions and repeatable quality.

Thermoforming & Machining

Forming and shaping techniques for large panels, bezels, and specialty parts, with CNC machining available for finishing or precision cuts.

Custom Enclosures

Plastic housings designed to protect electrical or mechanical systems from moisture, dust, impact, and UV exposure.

Joining

Adhesive bonding, plastic welding, ultrasonic welding and other joining technologies are available to complete you assembly design.

Material Expertise

Selection of engineering-grade plastics optimized for strength, heat resistance, chemical resistance, and aesthetics.

Secondary Finishes

Branding, coating, and surface treatments for improved appearance, wear resistance, or specialized functionality.

Protective Housings

Molded enclosures for electronics and mechanical assemblies.

Mounting Panels & Brackets

Precision components for secure system installation.

Cable Overmolds

Custom shapes to protect connectors and strain relief areas.

Consumer Product Casings

Durable, aesthetic finishes for retail-ready devices.

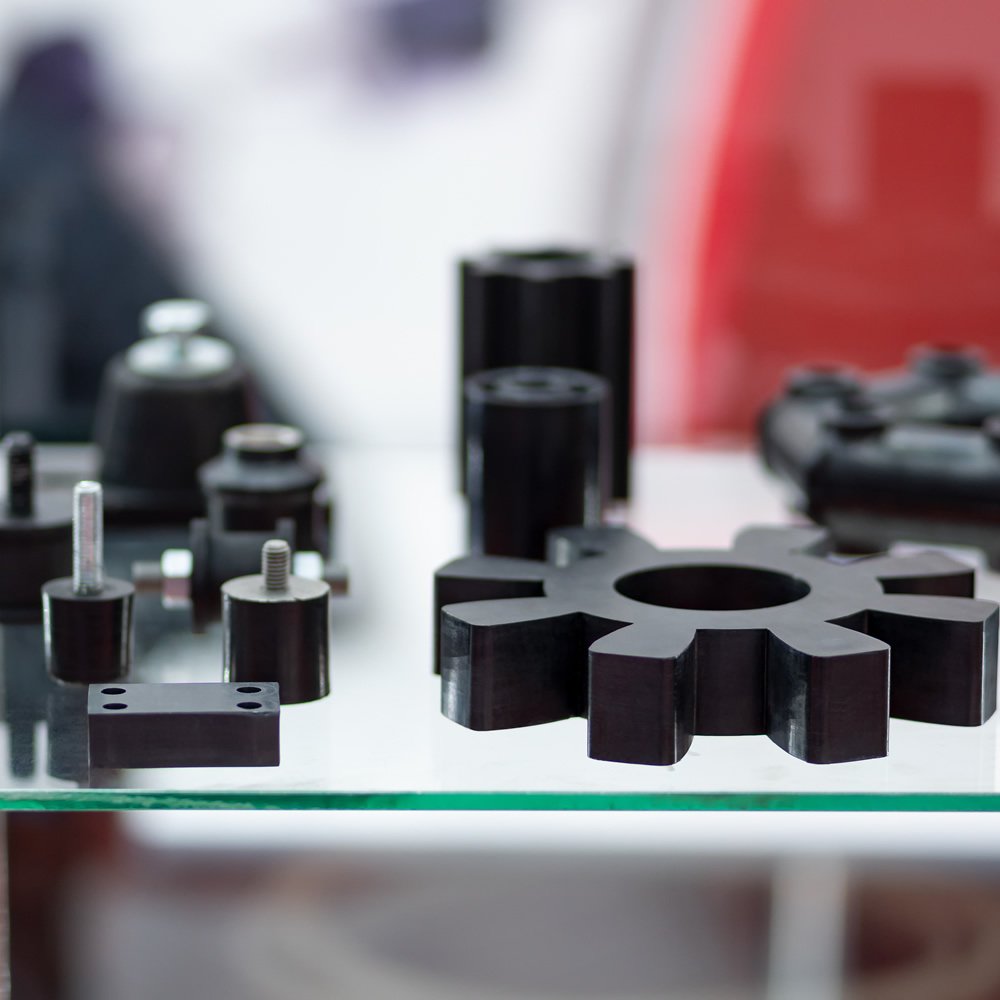

Mechanical Components

Gears, fasteners, spacers, stand-offs knobs, buttons, and other discrete mechanical components.